About mills

Mills have been a feature of the Scottish landscape for centuries. The number of operational mills was still in the thousands in the 19th and early 20th centuries. Mill owners had a range of power sources available, each with benefits and disadvantages. Up until the 19th century, waterpower was dominant in agriculture and industry until steam gradually became a viable alternative.

On this page you will find a brief overview of the types of mill that make up Scotland’s industrial heritage:

Windmills

Windmills became widespread in Europe from the Middle Ages. Thought to have been introduced to England first, the earliest reference to a windmill in Scotland dates to the 15th century. Windmills in Britain took the form of either Post Mills or Tower Mills.

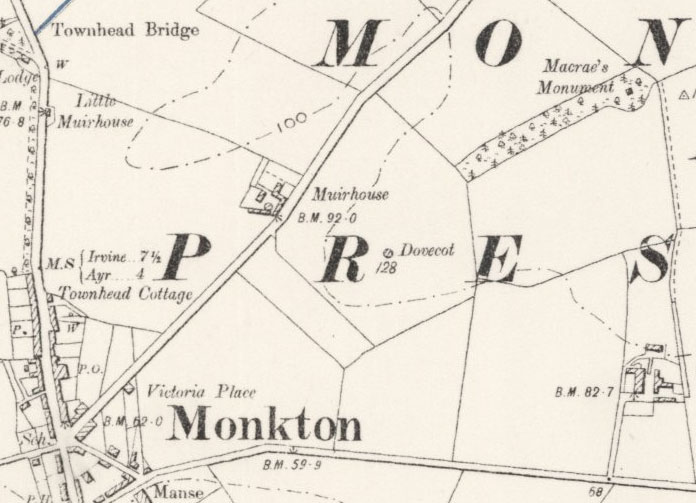

The Post Mill comprises of a wooden structure on a vertical post. The post, and the mill structure around it, can pivot to be turned into the wind. This was the earliest form of windmill in Britain. Later, the Tower Mill gained popularity. These were stationary towers, typically cyclindrical or tapering upwards in shape, and constructed of brick or stone. Only the cap at the top with the sails and drive-shaft would be rotated to the wind. After falling into disuse, some of the towers from these mills were later repurposed as dovecots.

(Courtesy of Historic Environment Scotland). View site on CANMORE

OS Six-Inch Ayrshire XXVII.NE, revised 1895, published 1897.

The geographical siting of a windmill was important and the mill’s surroundings could either aid its functioning or act as a hindrance to the wind. Vegetation and buildings might obstruct the wind, reducing velocity, but a hill with just the right contour could cause the wind to accelerate without creating turbulence. Thanks to the topography and the prevailing South Westerly winds from the Atlantic, much of the west of Scotland was suitable for wind power. And yet, in comparison to watermills, the country had very few windmills.

Wind offered a power source that was free and renewable but also unreliable. If wind speeds were too low the mill would be able to work only very slowly. On the other hand, if the speeds were too great it could become dangerous to work the mill, requiring the sails to be adjusted. The optimal wind conditions might occur during the night when there was no one available to operate the mill or the miller might need to work through the night to make the most of the power available.

Despite the limitations, wind was a valuable resource where alternative options were unavailable. For example, Whithorn’s 18th century tower windmill acted as the town mill, taking a central role in the local economy.

OS Six-Inch Wigtownshire XXXV.NE, revised 1894, published 1896.

Animal Powered Mills

The precise date when animals were first used to drive machinery is unknown but it is thought to go back to prehistory. Horse gins (from ‘engines’) were popular for a range of processes in agriculture, manufacturing, and mining. In the horse driven corn mill for example, the horse would walk in circles to turn a shaft which then turned a spur wheel and rotated the millstones to grind the corn. More unusual examples of animal power include a human operated treadwheel for paper presses and the dog-driven spit. Horse gins for threshing grain were a common sight in 19th and early 20th century Scotland, and are readily identifiable on OS mapping, even if unnamed.

Animal powered mills were cheap to construct and could be used almost anywhere. If multiple animals were used they could even rival the potential power of a medium watermill. However, horses could not work for more than 8 hours a day and there was the ongoing cost of animal fodder. After the 19th century, the popularity of animal powered mills waned.

Watermills

Watermills use either the weight or the force of running water to drive a waterwheel, and in turn, to power machinery. Most commonly, water is diverted from a river to flow onto a water wheel but mills can also make use of tides, lochs, artificial ponds, or the water wheel can be placed directly in the river.

Floating Mills were first used in Europe in the 6th century. Typically, the milling machinery would be placed on a boat and a waterwheel suspended in the river to be powered by the river current. Alternatively, the mill could be attached to or suspended from a bridge. There were a handful of documented examples of this type of mill in Britain and they were far more common in mainland Europe.

The Tide or Sea Mill is located on an estuary to take advantage of the current produced by the tide to the move a waterwheel. A major benefit of tidal mills was that they tended not to suffer from seasonal fluctuations in water availability. They were most popular at the mouth of smaller streams in southern England but were an important source of power for the eastern coastal burghs of Scotland too. Unfortunately, the schedule of tides is often at odds with the human working day, making them less suitable for large commercial enterprises.

Norse Mills or Horizontal Mills involved the driving wheel being placed horizontally, either directly in the stream or on a lade. These were typical in Shetland and Lewis.

The most common type of watermill in Scotland diverted water from a river or water body such as a loch or artificial pond, to a vertical waterwheel. The names given to the different types of vertical waterwheel (undershot, breastshot, overshot, and pitchback, or backshot) refer to the direction of turn imparted by the water and height at which the water reaches the wheel. The suitability of each wheel type for a particular mill depends on the power requirements of the mill, the volume of the flow and channel long profile of the river, and any infrastructure delivering the water to the wheel.

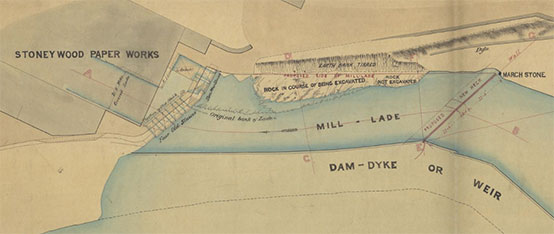

Watermills are part of a system. Some locations are naturally suited to provided waterpower while others require the construction of associated mill features. It may be necessary to build a reservoir, dam, or pond to store water and raise it to desired height. A mill lade1 brings water from the river or reservoir to the waterwheel then returns it to the river, with weirs and sluice gates controlling the flow. The construction of such infrastructure required a high level of skill and technical knowledge. The Stevenson firm, although better known for their lighthouses, was one company engaged in the engineering of the landscape for mills in Scotland.

George Gordon Jenkins, Stoneywood - Plan and sections of intake mill-lade at Paper Works, 1876.

MS.5862, 126. (View on maps website)

Even the most advanced engineering and scientific improvements could not always compensate for variations in water availability. Many mill owners complained of a lack of water during the summer or had conflict with neighbouring mills over water supply. Before the Factory Act of 1847 restricted working hours, it was common practice for mill workers to perform gruelling long days to compensate for any periods when the mill could not operate.

Steam Mills

The first machines to resemble what we currently think of as a steam engines were developed in the late 17th and early 18th centuries, to address the problem of flooding in mines. The Newcomen engine (named after its creator, Thomas Newcomen) was the first to achieve commercial success. These engines were best suited for pumping water at coal mines. The Newcomen engine made it possible to extract coal from much greater depths than was previously possible. However, these engines consumed vast quantities of fuel and their irregular motion rendered them unsuitable for most manufacturing purposes.

The 18th century witnessed many alterations to the steam engine to improve its safety and fuel efficiency. Scottish engineer and inventor, James Watt, famously began working in 1764 on the University of Glasgow’s model Newcomen engine before being granted a patent for his condensing engine in 1769. Watt later went into partnership with Matthew Boulton of Birmingham, England, and together their business manufactured hundreds of steam engines for use world-wide. Although Watt and Boulton are the best known innovators of steam engines, numerous other inventors and engine manufacturers contributed to the growth of steam power in Britain.

Steam mills were free from the geographical and seasonal restrictions that wind and watermills suffered from. A steam engine could be located anywhere, worked day and night, all year round and eventually even became portable. But engines required a large amount of capital to purchase, install, operate, and maintain. The early engines in particularly demanded large quantities of coal as fuel. Coal prices, which varied across Britain, often in relation to distance from a coal mine, were a major consideration for a mill owner in the decision to adopt steam or not. For many mills it was simply not cost effective to use steam and others purchased a steam engine to use alongside a waterwheel or to act as a back-up for use in the drier summer months.

Attempts to quantify the contribution of steam to economic growth in Britain during the Industrial Revolution generally acknowledge that the diffusion of steam was not uniform. Steam power was embraced earlier in particular regions and industries than others and water persisted well into the 19th century. Researchers continue to investigate when and how steam overtook water as the dominant power source for industry.

from the Stevenson civil engineering plans. Acc.10706, 374. (View on maps website)

Further reading:

Bignell, B. (2013). Mapping the windmill : the Ordnance Survey in England. London.

Bishop, P. (2021). OS mapping of water mills. Sheetlines, 120, 11-35. View online PDF.

Bishop, P., & Muñoz-Salinas, E. (2013). 'Tectonics, geomorphology and water mill location in Scotland, and the potential impacts of mill dam failure'. Applied Geography (Sevenoaks), 42(C), 195-205.

Gauldie, E. (1999). The Scottish country miller 1700-1900 : A history of water-powered meal milling in Scotland. Edinburgh: J. Donald.

Hills, R. (1994). Power from wind : A history of windmill technology. Cambridge: Cambridge University Press.

Lucas, A. (2005). 'Industrial Milling in the Ancient and Medieval Worlds: A Survey of the Evidence for an Industrial Revolution in Medieval Europe'. Technology and Culture, 46(1), 1-30.

Malm, A. (2016). Fossil capital : The rise of steam power and the roots of global warming. London.

Mills in Scotland | National Records of Scotland

Nuvolari, A., Verspagen, B., & Von Tunzelmann, N. (2011). 'The early diffusion of the steam engine in Britain, 1700-1800: A reappraisal'. Cliometrica, 5(3), 291-321.

Reynolds, T. (1983). Stronger than a hundred men : A history of the vertical water wheel (Johns Hopkins studies in the history of technology ; new ser., no. 7). Baltimore ; London: Johns Hopkins University Press.

Shaw, J. (1984). Water power in Scotland : 1550-1870. Edinburgh: Donald.

Sisitka, J. (1997) 'Floating mills in London: an historical survey', Industrial Archaeology Review, 19:1, 21-30, DOI: 10.1179/iar.1997.19.1.21

Robertson, A. & Robertson, T., Historical Journeys along British Rivers website.

Robertson, A. & Robertson, T. (2022). Investigations into watermill locations and types on 34 river catchments. Edinburgh: Rigg Free Publications.

Notes

1. The name used is dependent on geographical region and time period. The lade is also referred to as a lead, leat, or mill race.